DELIVERY just £9.95

Hang and Frame Your Printed Panels

Hang high definition metal prints

Sublimated prints on metal panels and other substrates are increasingly popular for both photo-gift and fine art photography.

These fabulous images on metal look great floating away from the wall.

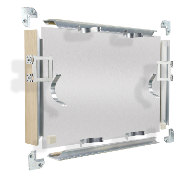

Working with leading metal print manufacturers, we have developed our elegant Aluminium Sub Frame Profiles. They bond to the back of a panel to space it away from the wall, keep it flat and provide options for safe and secure hanging.

The aluminium profile is joined to make a Sub Frame using LION’s unique moulded push-in corners. They have a combination of curves that create a slight concave at the contact face. Aluminium panels can flex during handling and transit and if this happens, a Sub Frame with sharp mitred corners can create dimples in the surface of the panel. This can also happen with MDF blocks bonded to the back of the panel, especially as the small block can allow significant flexing.

The corners are moulded in a light grey colour which tones with the aluminium profile. When customers flip over their beautiful art print, they’ll find a sleek, professional finish on the back. The Sub Frame gives them an easy and safe way to hang their picture on normal picture hooks. Or it can be secured using T-Screws.

LION Sub Frames come in two profile depths:

SUB15 floats the panel 15mm from the wall. With bonding tape pre-applied it is ideal for smaller panels and thinner substrates. Or, apply Heavy Duty Bonding Tape to the un-taped version for larger panels and thicker substrates.

SUB25 floats the panel 25mm from the wall. It is fixed with Heavy Duty Bonding Tape, making it suitable for most panel sizes and substrates.

Choose your finished style and we'll show you how...

-

Panel Hanging Plates

Self Adhesive Panel Hanging Plates are a quick and economical way to hang prints on substrates.

-

Sub Frame Profiles

Quick, simple & more rigid, add depth and rigidity by attaching a Sub-Frame to the back of the panel.

-

Art Frames

Give a refined finish with an aluminium Art Frame - the rebate hides the panel edges.

-

Tray Frames

This profile forms a tray - the panel is bonded to the lip of the tray, creating an eye-catching shadow gap.

Click here for Hardware & Accessories for Panels

Visit our showroom and workshop

Whether you're thinking of upgrading your equipment, refreshing your moulding chevrons or would just like to come along and chat to us, we'd love to welcome you to our LION mouldings showroom and framing equipment demo area. See what the latest equipment can do for your business.

Contact your Area Sales Manager or call our customer service team in Birmingham to arrange a visit.